Dental Crowns

The Dental Lab is a premier lab for dental crowns and tooth bridges. We provide compassionate and comprehensive results for dentists and their patients. Our technicians create aesthetic prosthetics with the latest developments and CAD/CAM technology. Technology helps to yield a precise fit and high aesthetics. Our technicians can mimic natural teeth with these life-like designs.

|

ZIRCONIA

Zirconia offers metal-free solutions that are perfect for anterior and posterior teeth. Zirconia crowns and bridges provide strength and high translucency. Restorations are biocompatible, strong, and aesthetic. Our lab offers esthetic, layered, and monolithic zirconia restorations. |

PFM

We make high-quality PFM restorations with CAD/CAM software and skilled technicians. porcelain fused to metal crowns are ideal because they combine strength and aesthetics. The porcelain layers bond to the metal. The results are great stability, strength, and lifelike aesthetic. |

LITHIUM DISILICATE

Lithium disilicate has true-to-nature shade behavior and greatest light transmission. Get long-lasting restorations with its resistance to fractures, chips, and cracks. We offer pressed and milled Emax lithium disilicate. Use the materials for crowns, bridges, inlays, onlays, and veneers. |

|

CELTRA DUO

Created with zirconia-reinforced lithium silicate, Celtra Duo possesses an ultra-fine microstructure. It has the ability to combine high flexural strength with a high glass content. The results are impressive strength and beautiful profiles. |

MARYLAND BRIDGE

The Maryland bridge use zirconia to provide strength and improved aesthetics. With CAD/CAM, our expert technicians ensure the bridge is a perfect fit in the patient's mouth. |

DENTAL VENEERS

Our lab makes porcelain veneers from lithium disilicate, zirconia, and synthetic feldspar. We also offer temporary veneers with PMMA material. Our variety of veneers cover a wide range of restorations that we can treat. |

|

FULL METAL CAST CROWN

Full-cast crowns are aesthetic, durable, and provide a superior fit. We combine CAD/CAM with industry expertise. This results in exceptional contouring and attention to detail. Crowns are available in biocompatible alloys in base, noble, white, and yellow. |

ACRYLIC PMMA

PMMA is for temporary cases, including crowns and bridges of any size. Temporary crowns also serve to provide function and aesthetics. They are ideal while the patient waits for the definitive prosthesis. |

INLAYS AND ONLAYS

Our expert technicians can create inlays that fill cavities. They can create onlays that serve as a filler of cavities and as a crown to prevent further damage or decay. |

Crown AestheticsThe Dental Lab is a proud provider of aesthetic crowns and bridges. We offer solutions for replacing natural teeth and covering large fillings. With tooth-colored restorations, we make permanent crowns from a variety of materials. The Dental Lab strives to maintain oral health and restore smiles.

|

Crown Labs

A dental crown is a restoration that covers or replaces a single tooth. Crowns can be hollow and placed over an existing tooth, or they can be solid to fill in an edentulous space. These solid crowns fasten to dental implants, which secure to the jawbone. The implants serve as artificial tooth roots and can be screw-retained or cement-retained. Dental crowns can be restorative or cosmetic. Use crowns to cover cracks, stains, cavities, or gaps in the teeth. They can also help maintain an existing tooth's size, strength, shape, and appearance.

Dental bridges are to replace missing teeth. Many crowns connect to fill an edentulous gap. They have a crown at both end and bridge of replacement teeth called pontics. The crowns on the end anchor onto natural teeth on both sides of the edentulous space. They can replace more than one missing tooth at a time. Both forms of dental treatments are popular alternatives to dental implants.

Dental bridges are to replace missing teeth. Many crowns connect to fill an edentulous gap. They have a crown at both end and bridge of replacement teeth called pontics. The crowns on the end anchor onto natural teeth on both sides of the edentulous space. They can replace more than one missing tooth at a time. Both forms of dental treatments are popular alternatives to dental implants.

Benefits of Dental Crowns and Bridges

|

Dental Crowns

|

Dental Bridges

|

Dental Crown Workflow

1. Case arrival. The impression scan arrives to the lab. Traditional impressions arrive via mail, Fedex, UPS, or courier. Digital cases arrive via digital portal on the computer.

2. Data entry. The data entry team enters the details of the case into our software. We track the details the product, shade, preferences, and any requested dates.

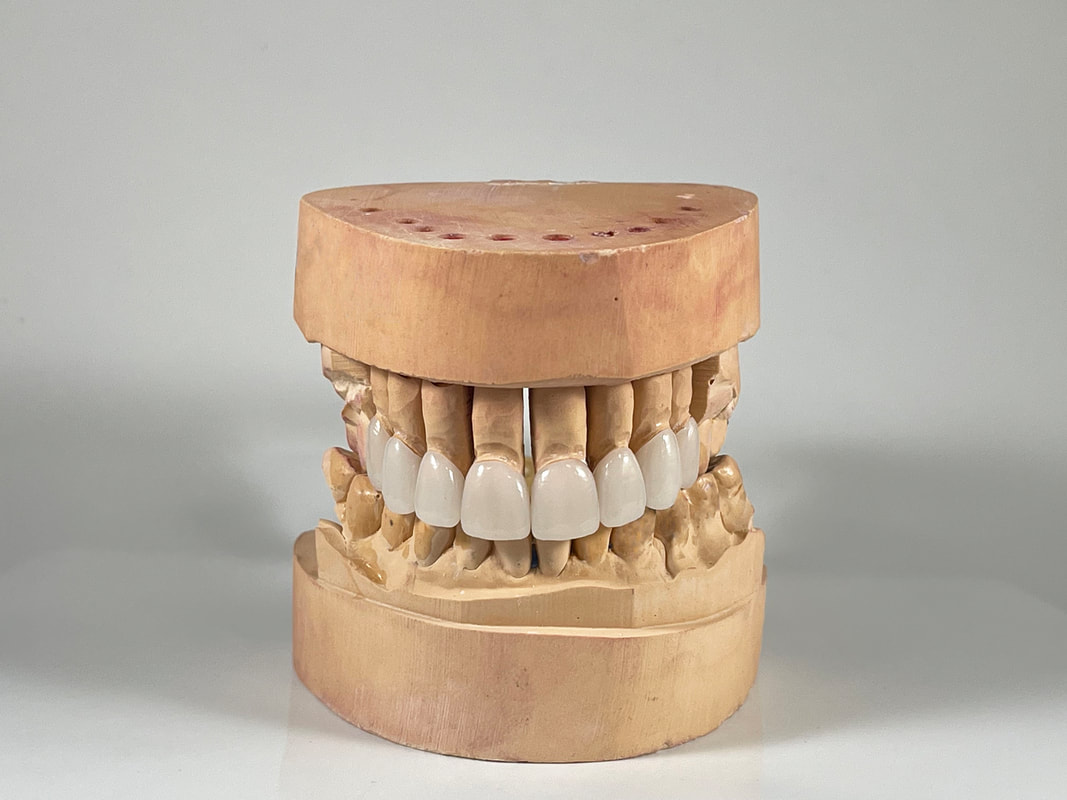

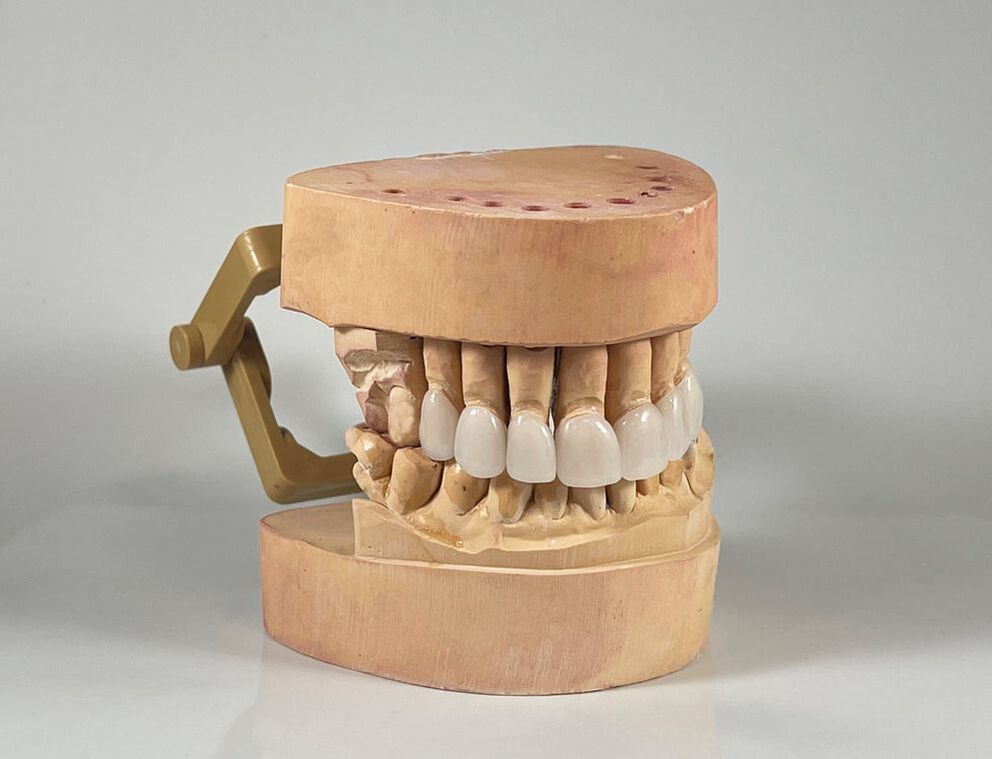

3. Modeling and design. Technicians create models based on the impressions. They pour, pin, articulate, and ditch along the margin line.

4. Fabrication prosthesis. The final design is then milled or printed in house. Prostheses can either be pressed, milled, or casted–depending on the selected material. With our digital workflow, our CAM team is able to load, nest, dry mill, wet mill, or print some of our restorations.

5. Case delivery. Quality Control inspects the finished restoration. The case is then invoiced and shipped to the dentist’s office.

2. Data entry. The data entry team enters the details of the case into our software. We track the details the product, shade, preferences, and any requested dates.

3. Modeling and design. Technicians create models based on the impressions. They pour, pin, articulate, and ditch along the margin line.

4. Fabrication prosthesis. The final design is then milled or printed in house. Prostheses can either be pressed, milled, or casted–depending on the selected material. With our digital workflow, our CAM team is able to load, nest, dry mill, wet mill, or print some of our restorations.

5. Case delivery. Quality Control inspects the finished restoration. The case is then invoiced and shipped to the dentist’s office.

Dental Crowns Cost

Costs can vary depending on many conditions. The material, the number of teeth necessary, and the method for securing the crown can impact the cost. Crowns can use many materials, including porcelain, plastic, PMMA, or metals. The severity of the case will determine which material is right for the patient.