Teeth grinding is particularly important to dentists because it can result in damage to the teeth or dental restorations. The activity can also induce temporal headaches and migraines, and temporomandibular disorders. Thankfully, with today's advancements, we are able to produce night guards that can effectively combat grinding and it's adverse effects. WHO IS JAMIE STOVER?Jamie Stover is the Senior Manager of Dental Lab Applications at Carbon, one of the world’s leading digital manufacturing companies. With over 23 years of Certified Dental Technician (CDT) experience, Jamie has had extensive exposure to all aspects of transitioning workflow from analog processes to digital–both clinically and in-lab. He is a seasoned author of dozens of publications for domestic and international trade journals and regularly lectures to dental professionals. In his role at Carbon, Jamie serves as a consultant for dental laboratories and dentists on streamlining production with a digital workflow and implementing new strategies for business growth and utilization of new applications. In 2021, he was awarded the National Association of Dental Laboratories (NADL) Merit Award for his contributions. Lastly, Jamie is a member of the Dental Technicians Alliance of the American College of Prosthodontics, Co-chair of the NADL Business Management Committee, and a fiscal officer on the National Board for Certification for Dental Lab Technicians. TRANSFERRING FROM ANALOG TO DIGITAL PROCESSESJamie opened up the webinar with a quote from Canadian Prime Minister Justin Trudeau, “The pace at which technology is evolving has never been faster in the history of the world and it will never again be slower than it is currently.” He explains how true this quote is, especially within the dental industry. Analog processes of waxing, casting, opaquing, and stacking porcelain over began transitioning to a digital process over a decade ago. However, what is relatively new and recent is digital removables and oral splints. Moreover, the increased demand for dental products caused by the rising rate of oral diseases has heavily impacted the need for faster production. Jamie stated that “When we move products and processes from analog to digital, we are really moving people.” As the infrastructure changes and technology advances in the medical field, people are more inclined to request those advances. 80 percent of prescriptions sent to dental labs are now either requesting full zirconia or products with a zirconia base. These are made through digital infrastructure. This is a particularly important time in the dental industry because we are at an intersection where art and craftsmanship are still relevant, but integrated digital process in designing, printing, and casting has streamlined the workforce and production. INCREASED NEED FOR NIGHT GUARDSKeystone Dental, a United States manufacturer of high-tech dental products and the producer of KeySplint Clear Printed Night Guards conducted a study on Bruxism and temporomandibular joint (TMJ) disorders. They found that bruxism, a chronic movement disorder identified by teeth grinding and jaw clenching, has adverse effects on a person’s physical and psychological well-being in many documented ways. Approximately 10 to 20 percent of the world’s population is impacted by bruxism. This disorder can add 10 times more pressure on the teeth compared to non-bruxing people. Over time, the damage from bruxism can result in TMJ, with 10 million people suffering in the United States alone. A poll by the American Dental Association (ADA News) reported that there is an increased prevalence in all of the industry trends: teeth grinding and clenching, chipped and cracked teeth, and temporomandibular joint dysfunction (TMD) symptoms. Here are some of the industry trends they reported:

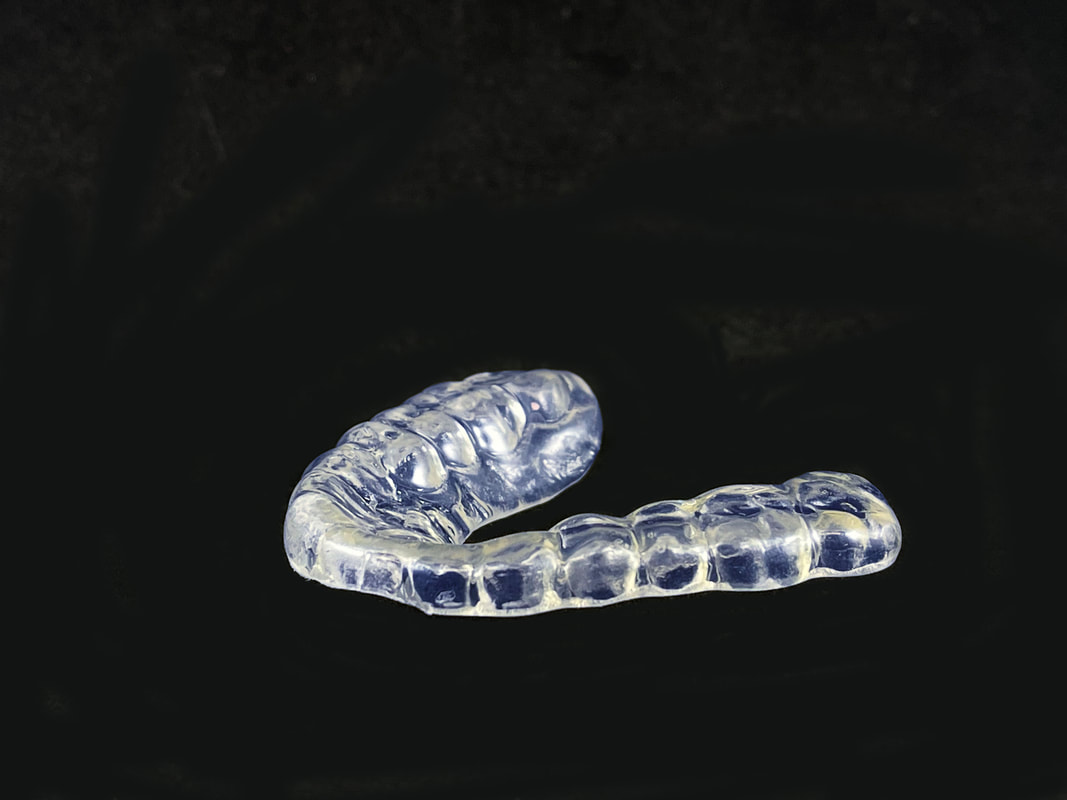

Dentists and dental laboratories are seeing an increased need for night guards and found a correlation between the increase and the COVID-19 pandemic. More stress-related conditions emerged during the pandemic and dentists are continuing to see them after. Jamie explained that a certain demographic was not previously impacted by bruxing behaviors, but now younger people and patients who did not typically experience the chronic disorder are. TRENDS IN THE DENTAL LAB INDUSTRYIn regard to dental laboratories, the most prominent challenge is the aging workforce of removable lab technicians and the shortage of new dental technicians. In a research project by the NADL, they found that over 60 percent of dental lab technicians are over the age of 55, and only 26.7% overall were listed as “most experienced” denture technicians versus “least experienced.” The reason is that there are simply not enough dental lab trade schools in the country, with only a handful left. This results in a shortage of new removable dental lab graduates to replace aging technicians. Because there is not an abundance of technicians or training programs, the current trend in dental labs is to hire inexperienced workers, start them in lower-level positions, and then gradually train them. Advancements in technology have significantly helped when it comes to training new technicians. Some steps from the traditional analog process have been completely eliminated, and some of the digital processes do not require any dental knowledge at all. Additionally, technology has enabled the captivity of knowledge in the digital realm. Experienced technicians are able to record their workflow and process, and can easily share it with the click of a button. However, another problem the dental lab industry is facing is that there are staffing shortages across all industries, so everyone is competing for those entry-level workers. CURRENT NIGHT GUARD PRODUCTION METHODSThe traditional method for fabricating night guards is very labor intensive, inefficient, and results in fits that vary wildly. Jamie described that most night guards today are still fabricated through analog with the traditional method with wax. There are a number of steps and materials used in the traditional process, and since everything is made by hand, there’s more room for human error. With every step, there is increased room for error, thus the reason why fits vary drastically. In addition, fabricating night guards through the thermoform method is less labor intensive and more efficient in terms of production. Many of the hands-on production steps are eliminated with this method, requiring less dental experience and skilled labor. However, they are not as robust as traditionally made night guards and result in less abrasion resistance and a varied fit as well. They are not a direct comparison to acrylic night guards when it comes to resisting abrasions. Jamie thinks of them as a, “really heavy-duty aligner.” Furthermore, the introduction of digitally milled night guards significantly reduced production labor, but the fit still varies, material costs can be high, and the milling time is inefficient. The milling process is very wasteful and directly results in high costs. Starting with a large mass of material, the technician cuts away at it until the desired shape emerges. The remaining material is often thrown away, with a small percentage that can be recycled. Specifically, with acrylic, the process is very slow because there is a risk of melting the material if it is spun and carved too quickly. On the other hand, milling zirconia is more efficient because the material is hard and strong. Lastly, digital carbon-printed night guards are significantly more efficient to make as they require less production labor, and improve the fit and material costs. Unlike the milling method, resin is used as the base material, and any remaining product can simply be transferred back to the original bottle and reused. The workflow is also almost entirely on computer-aided design and manufacturing (CAD/CAM) software, allowing technicians to design, adjust, and print through a computer. The physical fabrication of the night guard is done through a Carbon 3D printer. Dentists and patients have reported improved fit by removing room for human error and providing a more pure digital pathway. With both a hard and soft dental guard, the resistance against abrasions is extremely strong. BENEFITS OF A DIGITAL WORKFLOWThe most distinguished benefit of turning to a digital workflow is convenience. Clinicians have the choice to take impressions and scans either the traditional way or with a digital intraoral scanner. A digital scanner is not necessary to access a digital night guard. The dentist can simply send the traditional scan over to the lab where they will be converted to digital files and taken into the design software. Moreover, digital production mitigates the shortage of removable technicians. The software system removes all the manual steps and can quickly produce multiple night guards within a short period of time. The digital process only requires 6 steps: scan, design, output, print, cure, and polish. Digital labs also report an average labor savings of 65% compared to the traditional method. Finally, digital records allow labs to recreate dentures without needing a new impression. The original impression is saved on file as well as any updated versions. Technicians can easily and quickly print out a replica with the click of a button. Everything in a dental lab is a bespoke product for a specific case and patient. They have to do it consistently, reliably, and with scale. A digital workflow helps to ensure this. KEYSPLINT PRINTED NIGHT GUARDSKeystone offers KeySplint Printed Night Guards Soft. Their slogan is, “Effectiveness of hard splint. Comfort and flexibility of a soft splint.” A study on Leinfelder methods of measuring volume loss put Keysplint night guards through 400,000 cycles of testing. Compared to acrylic and thermoformed splints and guards that went through half the amount of cycles, Keysplint materials still had less volume loss in the end. They found that traditional night guards demonstrated good levels of abrasion resistance, but KeySplint Soft demonstrated outstanding levels. Overall, it was concluded that the Keystone material was safer and better for the patient because of its strength, resistance, and fitting. Today, over 2 million KeySplint Soft splints have been printed to date. 3D PRINTING IN DENTISTRY3D printing is popular in many industries because of its efficiency and speed. Some examples Jamie spoke about were 3D-printed shoes, bicycle seats, helmets, and even automobile parts. In medicine, he referred to a project by the University of North Carolina where researchers created 3D-printed vaccine patches. In dental labs, digital light processing (DLP) and digital light synthesis (DLS) 3D printers are mainly used. Here’s how they work:

Typically, the products are printed in layers that are visible and require dry time in between. However, advancements in technology have allowed a seamless print job where drying in has been sped up and you can no longer see the dividing line between layers. Other applications in dental labs besides mouth guards include models, implants, surgical guides, and soft tissue for gingival masses. HOW CAN THE DENTAL LAB HELP?We work with dentists, oral surgeons, and their patients to provide high-quality care, services, and products including night guards. The Dental Lab is one of the leading dental labs in the Philadelphia, Pennsylvania area. As a premier provider of dental services, our team understands the complexities of manufacturing custom dental products for our professional clients. Our products also include implants, removals, and more. If you are looking for assistance in how to approach the sale of a night guard to your patient or choosing the correct type, we are always here to help. In addition to being your trusted dental lab and an advisor, we want to help your patients achieve their comfort level, sleep, and new restoration. Sources: Bruxism, The Grind of the Matter Psychosocial Aspects of Bruxism: The Most Paramount Factor Influencing Teeth Grinding HPI poll: Dentists see increased prevalence of stress-related oral health conditions Valmont Research 2021 NADL Survey Bruxism: A literature Review Keywords:

The Dental Lab, KeySplint, Night Guard, mouth guard, Keystone, guard, patient, dentist, clinician, digital, analog, teeth grinding, bruxism, lab, dentistry, oral surgeon, computer, software, cad/cam, 3d printer, 3d printing, technology, abrasion resistance, Carbon, milling, custom night guard, custom night guards

0 Comments

Leave a Reply. |