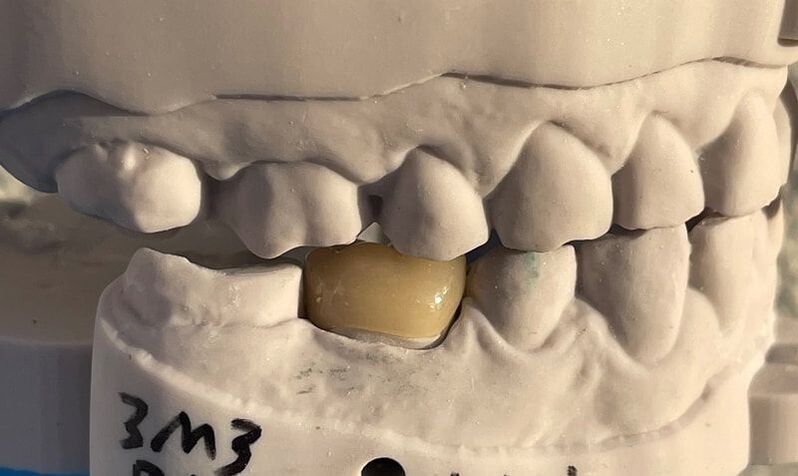

Lithium disilicate is a biocompatible material used to fabricate dental restorative products, such as crowns. It is classified as a particle-filled glass-ceramic and characterized by its high strength, fracture toughness, form, function, fit, and aesthetics. The material is one of the most widely used types of glass ceramics because of its mechanical and optical properties. Made up of an impressive chemical matrix, lithium disilicate glass ceramics are a favorable material for both dentists and laboratory ceramists because of its versatility and combination of durability and enhanced aesthetics. Productivity can be optimized using this material because prostheses can be fabricated through lost-wax pressing or CAD/CAM milling. Cementation options are also flexible; they can be cemented adhesively, self-adhesively, or conventionally. Preparation of the material is minimally invasive as dental restorations can be built without the need for veneering ceramic. However, it is beneficial to acid etch before cementation to achieve the ultimate bond strength. CHEMICAL MATRIX of Lithium DisilicateThe ceramic material has an interlocking matrix that is responsible for its strength and fracture resistance. The matrix consists of 70% fine, elongated, needle-like entangled lithium disilicate crystals and a minor amount of lithium orthophosphate crystals that are dispersed through the glass. This chemical composition also results in high shock resistance when it is processed. The sizes of the crystals range from 3 μm to 6 μm in length and 0.5 μm to 0.8 μm in width. What Can lithium disilicate Be Used For?Lithium disilicate glass ceramics can be used for a wide range of applications:

Processing Lithium DisilicateLithium disilicate can be processed through hot pressing techniques or with CAD/CAM milling procedures. PRESSED LITHIUM DISILICATEThe heat-pressed technique involves melting, cooling, nucleation of two different crystals, and growing crystals. This process needs to be continuously optimized to prevent defects. First, the restoration needs to be waxed up. Then, the wax needs to be invested and burned out. Finally, the lithium disilicate is pressed into the negative space in the wax. Pressing is the desirable production method as it enables the technician to get the full benefits of the material and produce several restorations in a single cycle. The pressable ceramic ingots come in different degrees of opacities, and technicians can also layer different shades and translucencies to achieve the desired outcome. MILLED LITHIUM DISILICATEThrough milling, CAD/CAM technologies can digitally mill ceramic blocks of lithium disilicate. The blocks are initially pre-crystallized, containing 40% of metasilicates in addition to lithium disilicate nuclei. They come in different degrees of translucency, depending on the size and distribution of the crystals in the glassy matrix. However, flexural strength is significantly influenced by translucency of the blocks. With the milling technique, the blocks undergo a two-step crystallization process, where they first arrive at the lab partially crystallized, and are later crystallized again. The pre-crystallized state has a moderate flexural strength of around 130 MPa, which allows for higher cutting efficiency, easier and faster workability and lower wear of the milling tools. The material can either be cut or ground. Cutting uses burrs designed to carve away at the material in a predictable and precise fashion. On the other hand, grinding uses diamond burrs that sand and wear down the material to the desired shape. However, the diamond particles can cause unevenness and as the burrs are worn down, the accuracy is reduced further. According to the Journal of Dentistry, microcracks with depths of 40-60 microns were reported when using the grinding method. Following milling, the prosthesis enters a heating cycle at 840°-850 °C for roughly 10 minutes. The cycle turns the metasilicate crystals into lithium disilicate, which significantly increases the flexural strength and fatigue resistance. MECHANICAL PROPERTIES OF LITHIUM DISILICATELithium disilicate is renowned for its strength and favorable wear behavior, allowing it to be used in all areas of the mouth. With a high flexural strength of 360 – 400 MPa, the material shows a low incidence of mechanical failures, such as debonding, fractures, or chipping. In 2010, Ivoclar Vivadent® found the fracture toughness to be 2.25 megapascals (MPa). Soft tissue response is excellent as well, with no inflammatory reactions present in vivo. LIHTIUM DISILICATE SURVIVAL RATEOther clinical studies by Clinicians Report® found lithium disilicate to have a low failure rate of about 5% even after 120 months of ongoing studies. For tooth-supported crowns, the survival rate after eight years was found to be 94.8%. The remaining failure percentage was due to breakdown in the cementation, but not in the lithium disilicate material itself. After five years for implant-supported crowns, the survival rate was 100%. OPTICAL PROPERTIES of Lithium disilicateLithium disilicate is an optimum material in regards to aesthetics due to its true-to-nature shade behavior, enhanced translucency, and ideal light transmission. The material’s color-matching ability with natural teeth is excellent. Fabricated through pressed micro-layered methods, the outcome is highly cosmetic. In regards to translucency, BMC Health reported in 2019 that lithium disilicate is about 30% more translucent than conventional zirconia. Dental Lab Near MeLooking for local dental labs that specialize in dental and denture services? The Dental Lab is a leading denture dental lab in the United States. We deliver all over the nation with our fast and reliable shipping services, making us a dental laboratory near you--no matter where you are. Dentists throughout Philadelphia and the surrounding region already turn to The Dental Lab for superior quality lithium disilicate crowns and other dental implants to restore their patients’ smiles. Our full-service dental lab offers lithium disilicate restorations through both options of milling and pressing. Contact us today to try lithium disilicate. We specialize in both pressed and milled restorations. Sources: Lithium Disilicate Current status on lithium disilicate and zirconia: a narrative review The Science Behind Lithium Disilicate: A Metal-Free Alternative Keywords:

The Dental Lab, Dental Lab, local dental lab, Lithium Disilicate, dental laboratory near me, Dentistry, Veneers, Restorations, Crowns, Dental lab near me

0 Comments

Leave a Reply. |