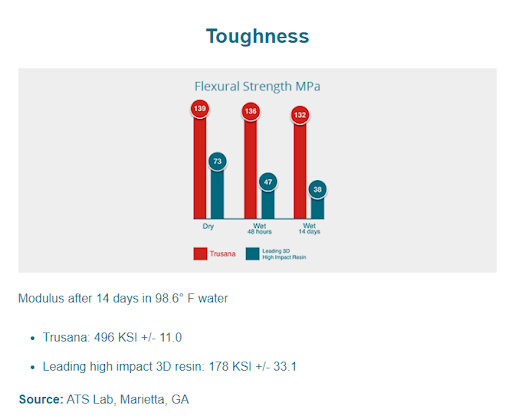

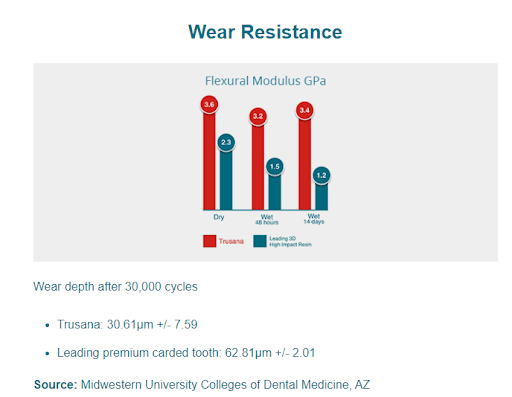

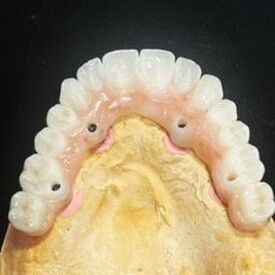

The Dental Lab is constantly evolving to better ourselves for our partnering physicians and their clients. When looking for new materials, we look for ones that are equal to or better than materials currently used in the lab for the last 50 to 60 years in terms of strength, durability, and aesthetics. WHAT IS MYERSON?In a recent webinar hosted by Zahn Academy focused on using Trusana for All-on-X cases, Certified Dental Technician (CDT) Trusana Director Susan van Kinsbergen represented Myerson and their product, Trusana. Myerson has been in business for over 100 years and is a globally recognized dental manufacturing company headquartered in Chicago with factories in the Caribbean country Trinidad and Tobago for over 70 years. While they specialize in removable dental products, Myerson is dedicated to the research and development of many innovative products. Their most popular products include Kenson denture teeth, Duraflex, Visiclear for partial removable frameworks, and elastic mandibular advancement (EMA) appliances for snoring and sleep apnea. WHAT IS TRUSANA?Trusana is different and superior to all other materials used so far with 3d printers in the dental industry. Trusana is a premium resin used to 3D print denture teeth for complete dentures, overdentures, or interim fixed complete dentures. Susan explains that the unfilled polymer has incredibly strong covalent bonds, a chemical bond that involves the sharing of electrons to form electron pairs between atoms. A stable balance of attractive and repulsive forces between atoms when they share those electrons is known as covalent bonding, and the balanced sharing of electrons between the bonded atoms results in the strongest bond known in nature. Other resins use fillers or add particles like nano-ceramic to try to achieve this strength. That is why they have to be placed on a roller for up to 12 hours before using them. If not rolled, any aesthetic or strength characteristics that those other resins had become dramatically reduced. The risk of using particles is that there is a higher likelihood of cracks and chips down the line as the resin does not seal perfectly to and around the particles. Susan said, “Nothing has been proven yet, but there are some concerns that these resins–as they wear down the appliance, [patients] are being exposed to these nano-particles.” On the other hand, Trusana doesn’t use particles for shade. Instead, it’s unfilled and uses pigments that are easily incorporated into the resin mixture. This product currently comes in six shades and has more in development. A team of polymer chemists developed the polymer to be super strong but also have an end result that is extremely aesthetic and lifelike. Moreover, with its unique chemistry–those covalent bonds–Trusana has shape memory. This means if you were it flex the material, it would return right back to its original shape. That's why it’s so perfect for the All-on-X device. It is currently validated for use on SprintRay and Asiga printers with additional validations to come. STUDIES DONE ON TRUSANATrusana has been tested by multiple schools, including the University of Connecticut: School of Dental Medicine, University of California San Francisco: School of Dentistry, Loma Linda University: School of Dentistry, and the University of the Pacific. With scientific and clinical leadership by Dr. Jeff Stansbury and Dr. Steven Sadowsky, the developers are not just chemists in some facility inventing a material that should work in dentistry. Instead, they are chemists with a working background in dentistry, designing materials that they know will work. Dr. Stansbury, Ph. D, is a professor of chemical and biological engineering at the University of Colorado. He is the Associate Dean for research at the School of Dental Medicine and the initial developer of the Trusana technology. Dr. Sadowsky is a Doctor of Dental Surgery and a Professor of preventative and restorative dentistry at the University of the Pacific. In addition, he is the Director of implant education. As far as chemistry is concerned, we have their real-life application of this material knowing what is needed in the patient's mouth for the prosthesis to survive. Studies at the universities and in the laboratories tested Trusana for using for All-on-X cases for the provisional phase of treatment, observing the prosthesis, and looking for breaking, chipping, or failure of the material. The university studies ultimately proved the results from the lab tests to be true, finding that there is low absorption of moisture, exceptional toughness, high levels of wear resistance, and high flexural strength. Low Absorption of Moisture A lot of materials tend to absorb a great deal of moisture because these other 3D printed resins contain acrylates in their chemistry, which are hydrophilic meaning they attract moisture. There’s a lot of moisture in the oral environment and with moisture, comes staining, bacteria, and odor. However, when compared to denture teeth and current generation 3D printed resins, Trusana hailed when it came to being hydrophobic. With the current generation resin resulting in 2% absorption, denture teeth at 0.4%, and Trusana at 0.3%, it is clear to see which material is most moisture-repellent. With the devices we’re printing, we’re dealing with a moisture-rich environment so the materials used need to be hydrophobic and effectively repel moisture. Exceptional Toughness To test its toughness, Trusana was tested against polymethyl methacrylate (PMMA) material after 14 days in water measuring 98.6 ° Fahrenheit. The study conducted by Applied Technical Services (ATS) Lab showed that Trusanna was three times stronger than PMMA with a megapascal (MPa) measurement of 3400 compared to 1200 MPa. Proven Wear Resistance Compared to premium denture teeth, Trusana tested two times more effective when it comes to wear resistance. The Midwestern University Colleges of Dental Medicine studied the wear depth of both materials after 30,000 cycles and saw that Trusana had stronger resistance by over half the amount of micrometers and the leading premium carded tooth. High Flexural Strength Testing after 14 days submerged in water, Trusana and PMMA materials were compared to one another to analyze which one is more efficient. The research found that Trusana’s strength increases when wet and doubles that of PMMA. Trusana was measured at 171 MPa while PMMA only measured 82 MPa. Researchers took note that Trusana’s characteristics and toughness escalate in water, while other materials tend to lose those properties. For other materials, a lot of their testing is done when dry, and the results tend to drop when in the mouth, a moisture-rich environment. PRINTING WITH TRUSANAThe steps to printing with Trusana consist of mixing, printing, cleaning, curing, and finishing. Mixing All the desirable characteristics of the chemistry are of the material itself. Before pigment is added, the material is crystal clear. As mentioned previously, no external nanoparticles are added to it. The only reason to mix is for the pigments to disperse throughout the resin. The accuracy of shade is dependent on proper mixing protocols using a rubber spatula to redistribute pigment. Printing Printing can be done on a validated printer, such as SprintRay or Asiga. It’s important to upload the Trusana settings into the printer to ensure the validated workflow. The proper settings will ensure consistency and accuracy and include the best types of reports. Files can be found and downloaded from the printer manufacturer's website. Cleaning Trusana printed products must be thoroughly cleaned to ensure the proper function and the safety of the user. Cleaning consists of a two-step approach: a dirty and a clean bath. Cleaning with 99% isopropyl alcohol, the product should be in the dirty bath for two minutes, and one in the clean bath. It is important to be strict in the timing of alcohol baths. If left too long, there is a drop in strength properties. Agitate the baths during cleaning, then dry with compressed air. Curing For the purposes of the webinar, Susan focused on using the Asiga Flash Unit when discussing curing. To validate resin on a printer, the entire process needs to be validated including the curing unit. Using a different curing unit is risky for the success of parts including strength properties and aesthetics, also for the safety of the patient. Uncured resin is dangerous especially if going into the mouth. She said that the Trusana denture should cure for 12 minutes on each side and cautions that only 70-80% is cured when it comes out of the printer and must cure outside of the system. Finishing Lastly, the dentures need to finish in a hot water bath. The bath relaxes the molecules of the resin and allows the material to gain 5-10% of strength during the process. The water should be set at 80° Celsius, with the dentures in a sealed bag submerged for 10 minutes. It’s vital that the temperature and time are exact. For example, if the water is too hot, it can affect the shade, making it darker–essentially cooking it. BENEFITS OF USING TRUSANATony Cirigliano, the Managing Partner of The Dental Lab and the Head of the Crown and Bridge Department joined the webinar to explain the pros of using Trusana for 3D printing in dentistry. He started off by stating the importance of not only choosing a material but the company behind the material as well. Tony chose to partner with Myerson and their Trusana dental product because it is a well-trusted company with a good track record, and their material is multifaceted–it can produce digital dentures as well as temporary restorations. Additionally, Tony explains that Trusana provides a more economical alternative to producing dentures. He addresses that traditional milling methods are inefficient, slow, labor-intensive, expensive, and the results are not as high in quality. Using PMMA is slightly more effective in all aspects, but it still does not result in the strongest material. However, Trusana takes every aspect to a new level and provides a more predictable approach. It’s faster, digital, cheaper, and the outcome is aesthetic, natural, lifelike, and provides optimal translucency. The conventional digital process has an outcome that is faster, more precise, and less labor-intensive. Because everything is designed through computer software, any adjustments can be made through the computer as well. The design can quickly be printed and duplicated if needed. Technicians can be quickly trained to use the digital setting–much faster than by hand with wax and carded teeth. This also means there is less hands-on work and less room for human error. When it comes to absorption, trusana is less absorbent of moisture, as Susan explains above. However, Tony expands to say that the material is also less absorbent when it comes to odor and stains as well. On the other hand, it is more shock absorbing, which is better for the healing implants and the opposing dentition. Over time, the prosthesis won’t collect stains, bacteria, or odor, which gives the patient perpetual bad breath. The work characteristics are excellent because the devices are in the patient's mouth for an extended period of time. During the healing, the doctor has got a lot of time to establish the vertical. This enables the ability to move on nicely to the definitive prosthesis. Trusana is ideal for long-term use, especially since the flexural strength increases in the presence of water. CASE STUDYTony described a case that was received that no milling machine or material currently being used could handle. The impression mold should be that the ball gauge size of the ledge to implant interface was over 30 millimeters long. However, restoration was able to be done using Trusana. Trusana was developed for difficult cases like these as well as for complete arches. There is such an epidemic of failure using traditional PMMA at about 10% for every set. He said cases like the one described are rare, but they do come in from time to time. Having the ability to work on these cases despite their infrequency is vital. Denture Laboratory Near MeThe Dental Lab is one of the leading denture labs in the country. We specialize in 3D-printing dentures and dental digital services. With our expedited shipping services, we can deliver all over the nation in just a few days, making us a local dental lab wherever you are. a full-service dental laboratory, with the ability to provide anything from porcelain veneers to surgical guides, full mouth reconstruction, single crown zirconia, and a full line of removable dental products. Tony Cirigliano has been in the industry for over 45 years. With his experience and that of the rest of the team, The Dental Lab is a leading restoration laboratory in the tri-state area. Please don’t hesitate to contact us with any questions or concerns you may have. You can view the full webinar with Myerson's Susan van Kinsbergen and The Dental Lab's Tony Cirigliano on our YouTube channel. Sources: Revolutionary toughness and lifelike translucency for 3D printing All-On-X applications On-Demand Webinar: DESS Implant Parts & Myerson's Trusana Resin for Screw-Retained Provisionals Keywords:

The dental lab, denture laboratory near me, 3d printing dentures, denture labs, dentures and dental, polymer, resin, 3d printing, FDA, implants, dentures, Dess, technology, digital dentures, removables, local dental lab

0 Comments

Leave a Reply. |