Digital dentures are dental prosthetics that are fabricated through a digital workflow. Using digital intraoral scanners, computer-aided manufacturing and design (CAD/CAM) technology, 3-dimensional (3D) printers, digital mills, and skilled denture technicians, finished dentures can be created. The digital denture process is minimally invasive and only requires a few appointments to get the dental impression and to place the prosthesis. Dental CAD/CAM software allows dental technicians to create accurate and reliable products virtually, and then bring them to life through 3D-printing or milling in hours. What are Dental Dentures?Dental dentures are custom-made removable prosthetics designed to restore aesthetics and function in edentulous patients. They serve as a replacement for missing teeth and the surrounding tissues. There are two types of dentures: complete and partials. Complete dentures are used for fully edentulous patients–or when all the teeth are missing from an arch. On the other hand, partial dentures are used when there are some remaining natural teeth left in the arch. Digital Denture Workflow

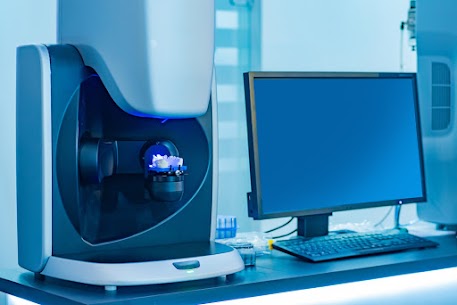

Dental ImpressionsImpressions are first taken by the dentist either with traditional alginate impergum or with a digital intraoral scanner. Traditional scanning methods are the preferred method for taking impressions and bite registrations for most dentists. Using molding material, dentists take physical copies of the patients’ mouths, which are then converted by a CAD/CAM and modeling team into a digital file. However, advancements in technology have led to the development of intraoral scanners that use a scientifically proven way to accurately record the bite. Digital impressions allow dentists to quickly scan full arches and send them to the lab via digital portal. CAD/CAM DentistryComputer-aided design and manufacturing technology is utilized to create perfect-fitting dentures. The advanced programming technology enables more accurate and predictable results by allowing the technician to see the prostheses on screen before even being manufactured. 3D prototypes are designed to scale, improving fit, turnaround and chairside time, and outsourcing and manufacturing costs. CAD/CAM software can be integrated with many other digital machinery to efficiently automate scanning, milling, and polishing processes. As a result, the digital denture workflow can be completed in as little as three appointments. Printing and MillingDepending on the type of denture–complete or partial–the gingival bases can be fabricated through additive or subtractive manufacturing methods. Through additive 3D-printing, complete dentures are produced by gradually depositing increments of liquid resin at a time until the desired shape is obtained. Subtractive manufacturing consists of digital milling machines carving away at single monolithic milling pucks of plastic-like PMMA material to create partial dentures. The prostheses are thoroughly cut out by a rotating drill with direction from CAD/CAM design. Digital FileDigital dentures can be stored in the digital file indefinitely. The digital scans and designs created by the CAD/CAM team can be accessed by both the dentist and lab at any time. At the click of a button, digital dentures can be printed, simplifying production and costs with the economical equipment. Dentists will have access to a digital file where they can review, track, or request changes to a case. Every change is recorded and saved onto the computer, meaning technicians can retrieve, duplicate, send, and store their designs with a click of a button. It is more efficient and beneficial to the patient for dentures needed in the future. When it comes time to replace the dentures, every set will be identical and consistent with one another because the storage of the CAD/CAM design allows technicians to retrieve previous files at any time. Digital Dentures Key TakeawaysThere are many benefits to 3D-printed dentures, but the main takeaways are that they offer a fast turnaround time thanks to the advanced technology, they are stronger and more secure than conventional dentures due to the accuracy of the scans and designs, and that dental labs can now deliver predictable results using digital dentistry coupled with the skills of creative dental technicians. Digital Denture Labs Near MeLooking for dental labs for dentures? The Dental Lab is specialized in denture and dental services. With our expedited shipping services, our products can be delivered directly to you in days, making us a dental lab near you--wherever you are. With digital dentures, we are changing the way dentists view dentures. We can help patients feel comfortable smiling, all while knowing their denture fits and functions, thanks to new advanced digital technology. The Dental Lab has technical support and readily available technicians to troubleshoot. We want to help you achieve what is required to get a perfectly fitting restoration. Contact us today for questions, concerns, or to send a digital case. Sources: Dental Health and Dentures Digital Versus Conventional: Denture Tooth Bond Strength Put to the Test What is Digital Dentistry? Keywords:

The Dental Lab, Dental Lab, Dental dentures, denture labs near me, dental labs for dentures, digital dentures, denture and dental, digital denture, dental lab near me, dentistry, 3d printed dentures, dental cad cam, cad/cam dentistry, conventional dentures, analog, traditional dentures

0 Comments

Leave a Reply. |